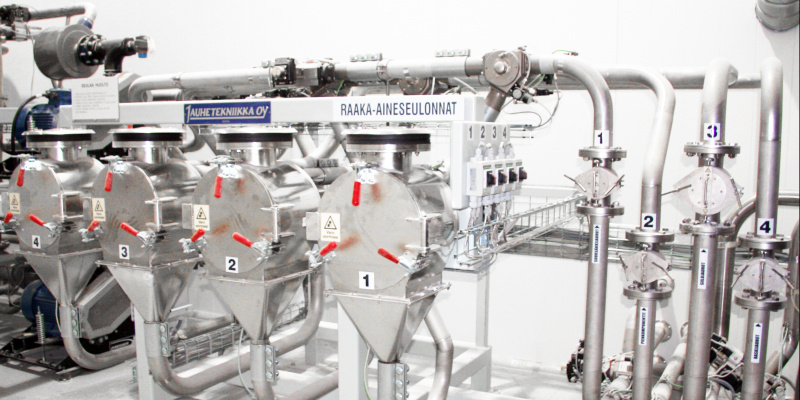

Powder Technic Pneumascreens can be used for the screening of powders and granular materials as part of a pneumatic conveyor line. Our Pneumascreens can be used with both vacuum and overpressure lines.

OPERATING PRINCIPLE

Material to be screened during operation is fed into the feeder port of the screen. The powder is run inside the screen to the drum section, where blades turning in the direction of the drum force the material through the drum. The material passing through the drum is ejected through the discharge port at the bottom of the screen.

THE STEEL PLATE SCREEN DRUM GUARANTEES DURABILITY

- Made of perforated steel plate, the screen drum offers unparalleled reliability, durability and economy compared to conventional nylon/steel mesh drums.

SUITABLE FOR USE IN THE SCREENING OF NEARLY ALL TYPES OF POWDER, INCLUDING EXPLOSIVE MATERIALS

- Construction: carbon steel or stainless steel

- Screen drum perforation size: 0.15-10 mm

- ATEX 20/21 zone classification inside, ATEX 22/unclassified outside

WIDE CAPACITY RANGE

- Wide capacity range, depending on the material being screened and screen perforation size: 1-15 t /h

EASY TO CLEAN

- Thanks to the hinged hatch, the screen drum is easy to inspect or change when switching grades.

RELIABLE EQUIPMENT CONSTRUCTION

- Our expertise in material handling ensures operational reliability.

- We use only the highest quality materials and components.

DETAILS DESIGNED TO MEET CUSTOMER SPECIFICATIONS

- Each and every detail is custom-tailored to meet customer specifications.